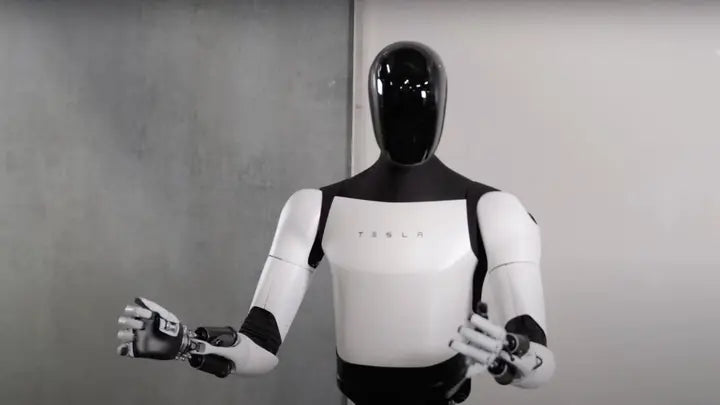

A general-purpose bipedal robot aimed at “dangerous, repetitive, or boring” work—built around Tesla’s data-first AI stack, torque-controlled electric actuation, and mass-manufacturable hardware choices.

Tesla Optimus is best understood as a strategic extension of Tesla’s autonomy program into the physical world. Where many humanoid robots begin with a “perfect body” and gradually layer intelligence on top, Optimus begins with a “scalable intelligence stack” and then builds a body that can be manufactured, serviced, and iterated like a consumer product. That sounds subtle, but it changes everything: the sensor choices, the compute choices, the training loop, and the near-term use cases.

The architectural bet is simple to state and hard to execute: if you can reliably understand the world through vision and learn control from large-scale data, you can build a robot that improves continuously rather than plateauing after hand-coded behaviors are exhausted. This is the same “learned capability flywheel” Tesla has chased in self-driving. The humanoid form is not the point—compatibility with human environments is. Optimus is shaped to use existing tools, fit through existing doors, and operate inside existing workflows.

That orientation is why factories and logistics matter so much in this story. They are not just places to sell robots—they are the proving ground where you can constrain the environment, collect repeatable data, validate safety, and turn incremental reliability gains into real ROI. A robot that is 95% capable in a factory setting can still be economically valuable. A robot that is 95% capable in a home setting is still a liability. Optimus is clearly tuned for the first world, not the second—at least for now.

The result is a humanoid program that may look less flashy than parkour-grade robots in short clips, but could be more disruptive over time if Tesla delivers on volume manufacturing and a stable autonomy stack. The most important question is not “Can it do a cool task on stage?” It’s “Can it do a boring task every day, safely, with a failure rate low enough that a manager stops worrying about it?”

58 / 100

62 / 100

66 / 100

84 / 100

90 / 100

54 / 100

| Spec | Details |

|---|---|

| Robot owner | Tesla |

| Program goal | General-purpose bipedal robot for unsafe / repetitive work |

| Announced | 2021 (AI Day) |

| Form factor | Human-scale humanoid |

| Actuation | Battery-electric, torque-controlled joints (no hydraulics) |

| DoF / actuators | ~28 body DoF (commonly cited in public breakdowns; may vary by generation) |

| Hands | Dexterous hands; public sources often cite ~11 DoF per hand (implementation may evolve) |

| Sensors | Camera-centric perception; joint sensing; tactile / force sensing implied for manipulation |

| Primary perception bet | Vision-first (camera-centric scene understanding rather than LiDAR-heavy stacks) |

| Onboard compute | Tesla in-house inference hardware (FSD-derived SoC lineage is frequently referenced) |

| Training compute | Tesla AI training clusters (public reporting indicates compute strategy has shifted over time) |

| Near-term target env | Factories / warehouses / structured workflows |

| Public spec reliability | Medium (Tesla shares demos and goals; fewer audited performance metrics) |

Perception. Optimus inherits Tesla’s core belief that vision can be the primary “sensor of truth.” In practice, this means using cameras to interpret the scene and learning depth, object boundaries, and affordances through neural networks. The upside is cost and simplicity: fewer expensive sensors and fewer calibration problems across a production fleet. The downside is that every corner case becomes a learning and validation problem rather than a hardware shortcut.

Planning and control. Most humanoids historically relied on carefully engineered control pipelines with scripted behaviors. Optimus trends toward learned behaviors trained from demonstrations, with classical control still present where it provides stability and safety. This hybrid is the pragmatic path: neural nets learn high-level task structure and perception-to-action mappings, while classical control can enforce constraints, smooth motion, and cap forces. The key question for readers is not “Is it neural?” but “Where is it neural, and what guardrails exist when it’s wrong?”

Training loop. A humanoid’s real advantage comes from a tight improvement cycle: collect demonstrations, train new policies, deploy, measure failures, then repeat. Tesla’s best-case scenario is a closed loop inside its own operations: internal tasks produce repeated data, repeated data produces model improvement, and model improvement unlocks more tasks. This is why factory-first strategy is so rational. It produces clean training distribution and measurable KPI goals.

Embodiment choices. Optimus avoids “hero hardware.” Electric actuation is chosen for manufacturability, serviceability, and energy efficiency. The robot’s body proportions and reach appear built around human spaces, not lab obstacles. This has a subtle effect: the robot is less likely to chase extreme performance (like acrobatics) and more likely to chase comfort, stability, and safe motion—attributes that matter when humans share the floor.

Bottlenecks. The next phase of capability is not just better walking. It’s better “hands plus judgment.” You can think of this as a three-part stack: grasp reliably, manipulate with force awareness, and recover when something goes wrong. That recovery layer—replanning, re-grasping, or asking for help—defines whether the robot is a novelty or a worker.

| Priority | Pick | Why | Tradeoff to accept |

|---|---|---|---|

| Best first environment | Tesla-owned factories | Controlled workflows, clear KPIs, immediate feedback loop, and the ability to instrument every failure without customer churn. | Early wins may not generalize to messy third-party sites without additional sensing, tooling, or constraints. |

| Highest ROI task class | Material handling + kitting | Repetitive motions, predictable objects, and measurable throughput. Failures are observable and fixable through iteration. | Manipulation reliability must reach “boring” levels; small error rates still hurt shift-level performance. |

| Most realistic near-term goal | Assisted autonomy (human-in-the-loop) | Teleop + autonomy hybrids let the system learn while reducing safety risk. It creates training data without pretending the robot is finished. | Economics depend on supervision cost; too much human oversight can erase the value. |

| Long-term bet | General-purpose shift worker | If the learning loop compounds and hardware cost drops, the robot becomes a deployable labor unit across many industries. | Requires a reliability threshold that is far above “demo success.” The last 10% is the hard part. |

Robotics is not graded on intelligence in the abstract. It is graded on repeatability: can the robot perform a task, recover from small disruptions, and do it again—hundreds of times—without becoming a safety problem. Below are representative workloads that fit Optimus’ likely early sweet spot.

| Scenario | Environment | Required capability | What success looks like | Readiness signal |

|---|---|---|---|---|

| Tote transfer | Warehouse aisle | Reliable grasp + stable walking + obstacle awareness | Moves totes from shelf to cart with near-zero drops across a shift | Good first KPI because failures are obvious and fixable |

| Kitting / line staging | Factory floor | Pick-and-place + object ID + force-limited handling | Stages parts in correct bins with consistent cadence | High ROI if error rates are low enough to avoid rework |

| Simple assembly assist | Workcell | Two-hand coordination + fine placement + compliance | Holds, positions, or inserts components without damage | Great for assisted autonomy; hard for fully autonomous early |

| Visual inspection routing | End-of-line | Vision detection + routing decisions + safe carrying | Flags suspect units and routes them to a review queue | Pairs well with vision-first stack if lighting is controlled |

| Cleanup + reset | Shift change | Navigation + manipulation + safe interaction | Resets tools, clears debris, returns items to known locations | Often undervalued; can be a strong “boring robot” wedge |

The fastest way to ruin a humanoid rollout is to treat it like a single big launch. The correct approach is staged autonomy: constrain the environment, enforce guardrails, instrument everything, and only expand when the robot earns it with data.

Begin in a bounded area with known objects, known lighting, and predictable pathways. This sharply reduces edge cases, accelerates learning, and makes safety enforcement simpler.

Real work is messy. A useful robot can re-grasp, re-plan, and retry safely. Recovery behavior is what turns a demo into a shift worker.

If autonomy isn’t reliable yet, don’t fake it. Human-in-the-loop operation can still be valuable if it reduces physical strain and captures demonstrations for training.

Optimus is Tesla’s attempt to build a general-purpose humanoid worker. The program is aimed at tasks that are repetitive or unsafe, starting in structured settings like factories and warehouses.

Vision-first stacks can be cheaper to manufacture and easier to scale across large fleets. The tradeoff is that robustness comes from training and validation rather than expensive sensing. That makes the software loop the main product.

Public demos show meaningful progress, but “fully autonomous” should be defined as: operating for long periods, recovering from exceptions, and meeting safety thresholds with minimal human intervention. That level is typically achieved gradually through pilots.

Hands plus reliability. Walking matters, but manipulation under uncertainty (object variety, friction, occlusion, clutter) is the thing that determines whether the robot is economically useful across a shift.

Audited metrics: shift-length uptime, mean time between failures, unsupervised completion rates, and clear cost-per-unit at scale. The more “boring” the numbers look, the more real the robot is.

Robotics specs change fast. Where possible, prefer primary vendor pages and dated reporting. Add or revise links as new audited metrics emerge.